Low-density polyethylene, commonly known as LDPE, is one of the most widely used materials in flexible packaging. It is lightweight, flexible, and easy to process, which makes it a go-to choice for everyday packaging applications.

A classic example is the bread bag. Thin, clear, and soft to the touch, bread bags rely on LDPE because it can be blown into lightweight film while still holding up through distribution. Even at low thicknesses, LDPE stays flexible and durable, helping protect products without adding unnecessary material.

Where LDPE really stands out is sealing performance. It melts at a relatively low temperature and has a wide sealing window, allowing it to form strong, reliable seals even when line speeds change or conditions are less than perfect. This makes LDPE especially effective for products that leave small particles in the seal area, such as powders, baked goods, and snack foods. LDPE can seal through minor crumbs or residue, helping packages stay closed and products protected on the shelf and in transit.

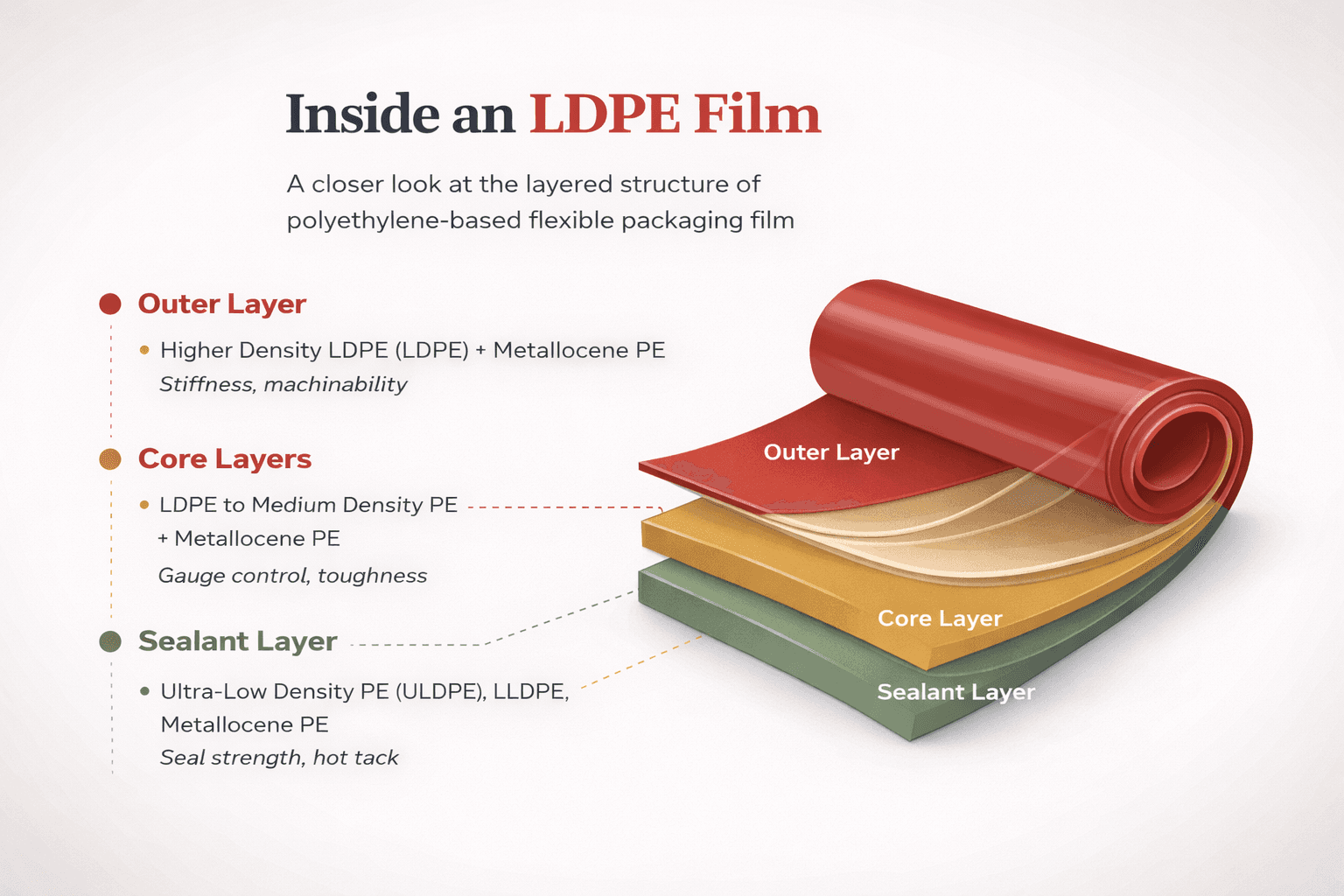

What is often overlooked is that an “LDPE film” is rarely a single material. In most modern flexible packaging, LDPE films are engineered structures made from multiple polyethylene layers, each selected to perform a specific function. A single film may include blends of low-density polyethylene, medium-density polyethylene, and ultra-low-density polyethylene, combined to balance strength, flexibility, and seal performance. Metallocene-based polyethylene is frequently added to improve toughness, consistency, and seal reliability, especially in demanding or high-speed applications.

These blends allow packaging engineers to fine-tune performance. Softer ultra-low-density layers can improve seal initiation and seal through contamination. Higher-density layers can add strength, stiffness, or better machinability. Metallocene resins help tighten property windows, delivering more predictable sealing and improved abuse resistance. The result is a film optimized for the product, the packaging equipment, and the real-world conditions it must survive.

LDPE also plays an increasing role in sustainability efforts. Post-consumer recycled (PCR) LDPE is now being incorporated into these multilayer films for both food and non-food packaging. While recycled content can slightly affect appearance or physical properties, careful formulation and layer design help maintain performance while reducing reliance on virgin resin. Applications like bread bags, e-commerce mailers, trash liners, and select food wraps increasingly rely on these engineered PCR blends.

LDPE does have limitations. Because it softens at relatively low temperatures, it offers poor heat resistance compared with other plastics. This can limit machinability and productivity in high-heat or high-speed packaging operations if films are not properly designed. Its softness also makes it more prone to scratching and scuffing, which is why LDPE is rarely used as the outer layer of a package.

For engineers, operators, and brand owners, LDPE is the material that keeps flexible packaging practical. From simple bags to complex laminated structures, LDPE-based films deliver dependable sealing, tunable performance through layered design, and growing options for recycled content. It may not always be visible, but it is often the layer doing the hardest work, quietly holding flexible packaging together.

Curious how layer design and resin selection impact real-world packaging performance? Explore more Packaging Made Simple insights on Admiral Packaging’s blog.

About the Author